Ürünleri İncele

Kalite Güvenceli Son Teknoloji

BorşenYerli

Üretim

%100 Yerli Üretici Sertifikası ile seri üretim

Kalite

Kontrol

Son teknoloji takibiyle daima en iyi kalite

Stok

Gücü

20.000 ürün çeşidiyle anında çözümler

HAKKIMIZDA

Sanayimizin gücüne

Hakkımızda

Sanayimizin gücüne

Borşen gücü katıyoruz

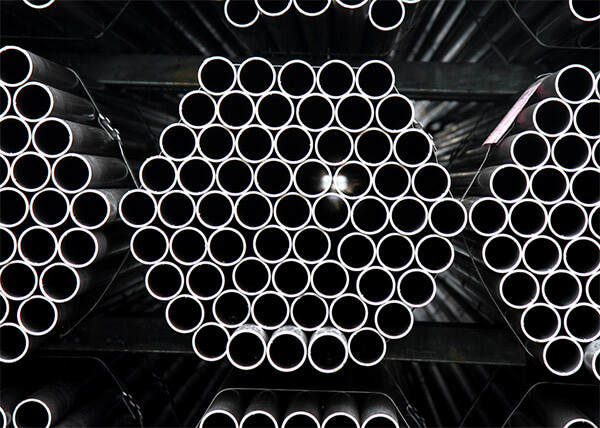

- Ø19 mm-Ø76.1 mm arası T.I.G kaynaklı tavlama ünitesine sahip üretim hattı,

- Ø88.9 mm-Ø219.1 mm arası Lazer kaynaklı üretim hattı,

- Ø19 mm-Ø76.1 mm arası Lazer kaynaklı üretim hattı,

- Dilme hattı,

Hakkımızda

SAYILARLA BORŞEN

SAYILARLA BORŞEN

Borşen

41

YILLIK TECRÜBE

1983 Yılından beri süre gelen kalite anlayışı

15

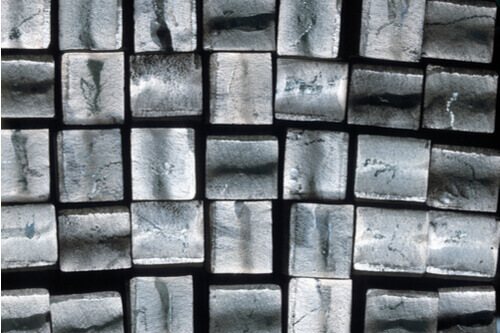

BİN TON

Yerli ve milli dikişli boru üretim kapasitesi

20

BİN ÇEŞİT

Ürün ile Avrupa’nın sayılı stokçusu

56

BİN METREKARE

İstanbul Fabrika, İstanbul depo ve Adana depo ile Türkiye’nin her yerinde

BORŞEN