Reading Borşen Certificate

TEST SERTİFİKASI

INSPECTION CERTIFICATE

EN 10204 : 2004 -

3.1

Sertifika No. / Certificate

No.

20160261

Tarih / Date : 28/07/2016

Sayfa / Page : 1 / 1

20160261

Tarih / Date : 28/07/2016

Sayfa / Page : 1 / 1

BORŞEN İş Emri No. / BORSEN Work Order No. :

20160262

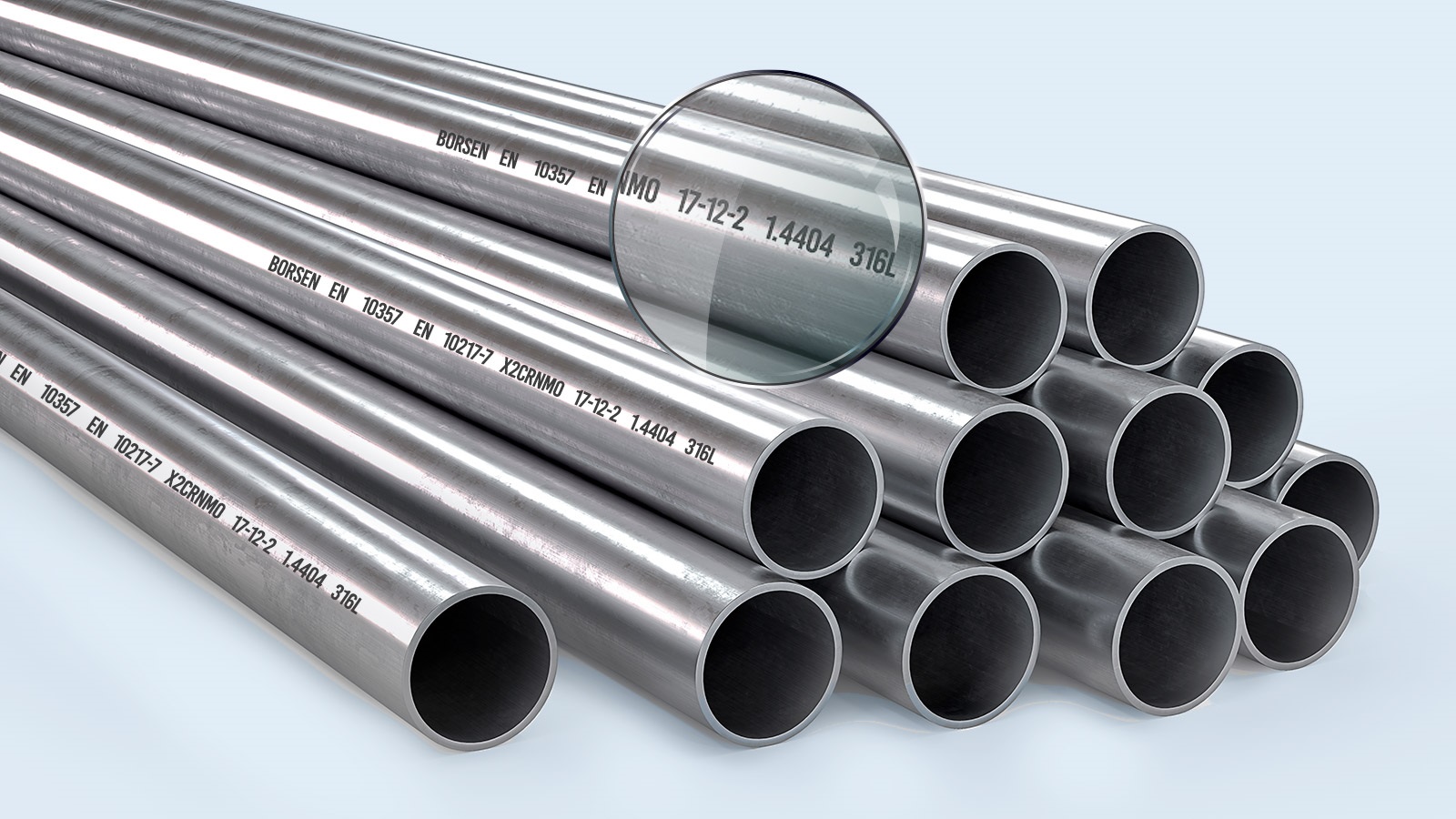

20160262

Ürün Tanımı / Product Description :

Boyuna kaynaklı paslanmaz çelik boru

Longitudinally welded stainless steel

pipe

Boyuna kaynaklı paslanmaz çelik boru

Longitudinally welded stainless steel

pipe

Kaynak Yönetimi / Welding Process :

TIG - GTAW - 141 (İlave metal yok)

(Without filler material)

TIG - GTAW - 141 (İlave metal yok)

(Without filler material)

Kaynak Faktörü / Joint Factor :

Z=1.0

Z=1.0

Spesifikasyonu / Specification :

EN 10357 EN 10217-7 TC1

EN 10357 EN 10217-7 TC1

Kalite / Grade :

X2CrNiMo 17-12-2 1.4404 316L

X2CrNiMo 17-12-2 1.4404 316L

Tolerans / Tolerance :

EN ISO 1127 D3 / T3

EN ISO 1127 D3 / T3

Isıl İşlem / Heat Treatment :

Çözelti tavlaması / Solution Annealing

(1040-1060 oC)

Çözelti tavlaması / Solution Annealing

(1040-1060 oC)

İç Kaynak Temizliği / I. D. Finishing :

Yapıldı / Bead Rolled :

Yapıldı / Bead Rolled :

Dış Yüzey İşlemi / O. D. Finishing :

Fırçalı / Brushed :

Fırçalı / Brushed :

Ürün Markalama / Product Marking :

BORŞEN EN 10357 EN 10217-7 X2CrNiMo 17-12-2 1.4404 316L Ø51 x 1.2 x 6000 858021 20160261 W2R TC1

BORŞEN EN 10357 EN 10217-7 X2CrNiMo 17-12-2 1.4404 316L Ø51 x 1.2 x 6000 858021 20160261 W2R TC1

| Sevk Kapsamı / Chemical Composition | |||||||||

| Sıra No. Item No. |

Boyutlar Dimensions |

Adet Pieces |

Miktar (m) Quantity (m) |

Ağırlık (kg) Weight (kg) |

Başlangıç

Malzemesi Starting Material |

Döküm No. Heat No. |

|||

| 1 |

Ø51 x 1.2 x

6000 |

931 |

5586.0 |

8426 |

Coil EN 10028-7

X2CrNiMo 17-12-2 1.4404 - EN ISO 9445 (EN 10249) |

858021 |

|||

| Kimyasal Kompozisyon / Chemical composition | |||||||||||

| Sıra

No. Item No. |

C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

Cr (%) |

Ni (%) |

Mo (%) |

Ti (%) |

Nb (%) |

N (%) |

|

İstenen REQ. |

max. 0.030 | max.

1.00 |

max.

2.0 |

max.

0.045 |

max.

0.015 |

16.5-18.5 | 10.0-13.0 | 2.0-2.5 | ---- | ---- | max.

0.11 |

| 1 | 0.0210 | 0.3260 | 1.2500 | 0.0032 | 0.0033 | 16.66 | 10.080 | 2.0200 | 0.0120 | 0.01300 | 0.0360 |

| Mekanik Test Sonuçları / Mechanical Test Results | ||||||||

|

Sıra No. Item No. |

Test No. | Test

Sıc. Test Temp. (oC) |

Akma dayanımı (RP0.2) Yield Point (RP0.2) (N/mm2) |

Kopma Dayanımı (RM) Tensile Strength (RM) (N/mm2) |

Uzama

(%) Elongation (%) A5 |

Sertlik Hardness HRB |

||

|

İstenen REQ. |

RT | min. 190 | 490-690 | Longitudinal min. 40 | ---- | |||

| 1 | 16-261 | 363 | 618 | 46 | ||||

| Göz ve Boyut Kontrolu / Visual and Dimensional Inspection | : Kabul / Acceptable |

| Açma Testi / Drift Expanding Test [EN ISO 8493 / ASTM A 1016 Sec.22] | : Kabul /

Acceptable |

| Ezme Testi / Flattening Test [EN ISO 8492 / ASTM A 1016 Sec.19] | : Kabul /

Acceptable |

| Eddy Current Testi / Eddy Current Test [EN ISO 10246-2 / EN ISO 10246-3 / ASTM E 426] | : Kabul /

Acceptable |

| Yüzey Pürüzlülüğü / Surface Roughness | : Kabul /

Acceptable |

| Burada

belirtilen malzemenin imalatının, numune hazırlığının, testinin

ve kontrolunun yukarıdaki standardlara ve şartnamelere göre

yapıldığını ve sipariş şartlarına uygun olduğunu beyan

ederiz. We hereby certify that the matarial herein described has been manufactured, sampled, tested and inspected in accordance with above standards and specifications and satisfies the order’s requirements. |

TESTLERİ YAPAN

TESTED BY

28/07/2016

SUAT PEHLİVAN

Doküman No: KK FR 03

ONAYLAYAN

APPROVED BY

28/07/2016

Rev No: 00 / Tarihi: 10.06.2010

BORŞEN BORU SAN. TİC. ŞTİ.

Dudullu Org.San.Böl.3 Cad. No:20

Y.Dudullu / Ümraniye / İstanbul / Türkiye

Tel: 0216 466 37 05

Fax: 0216 420 65 63

borsen@borsenboru.com

www.borsenboru.com

1

The registered logo, contact information,

website address, e-mail, and full address declaration of the manufacturer must

be included in the certificate.

2

ISO 9001:2000 accreditation confirming the

quality management system certificate of the company and the official

registered institution from which it was obtained must be specified.

3

The commercial registry identification details

of the company placing the order must be stated on the certificate.

4

The order number of the customer must be written

on the certificate.

5

The manufacturer must definitely give an

acceptance number for the order it approves by specifying it on the certificate

and the date this number was allocated must also be stated.

6

A general description of the manufacturing phase

of the tube in question must be stated on the certificate.

7

The equivalent of the welding method applied in

the manufacturing phase, both in writing and in the standard literature, must

be written.

8 It reveals that the control processes for welding

conducted during production phase are realized with ratio of 100%.

9

It must be stated according to which standard

the manufactured tube is manufactured.

10

The stainless quality of the manufactured tube

must be stated.

11 The tolerance range must be stated on the

certificate according to the manufacturing standard.

12 It indicates whether the heat treatment /

annealing process was performed at an average temperature of 1050 degrees

Celsius during the manufacturing phase or not

13 It is mandatory to provide information about the

internal weld cleaning of the tube during

manufacturing.

14 It is stated whether the brushing process was

applied to the outer surface of the stainless tube during manufacturing or not.

15 Since the marking is accepted as the identity of

the manufactured tube, it is mandatory to be stated on the certificate.

16 It is the section where all the information

about the product to be shipped is included.

( Dimensions – Number – Quantity – Weight – Material Standard – Heat Number )

( Dimensions – Number – Quantity – Weight – Material Standard – Heat Number )

17 It is the section where the chemical data about

the manufactured tube is included.

18 The manufacturer company must apply mechanical

tests according to the manufacturing standard and show the results it obtains on

its certificate. In this section, the optimal reference range should be

compared with all numbers and parameters obtained by the manufacturer's

laboratory.

19Conformity of destructive and non-destructive

tests being conducted.

20 Declaration of conformity covering the entire certificate.

21 Company stamp, approval date and the name and

signature of the authorized person performing the quality control must be placed.